Designed in conformation with industry defined standards, the range of our Control system is running high in demand in the market due to its remarkable attributes such as outstanding performance, easy installation, high energy saving, reliable operations and longer working life. To ensure these quality attributes, we manufacture the complete range making use of only best grade raw material and latest technologies by our professionals.

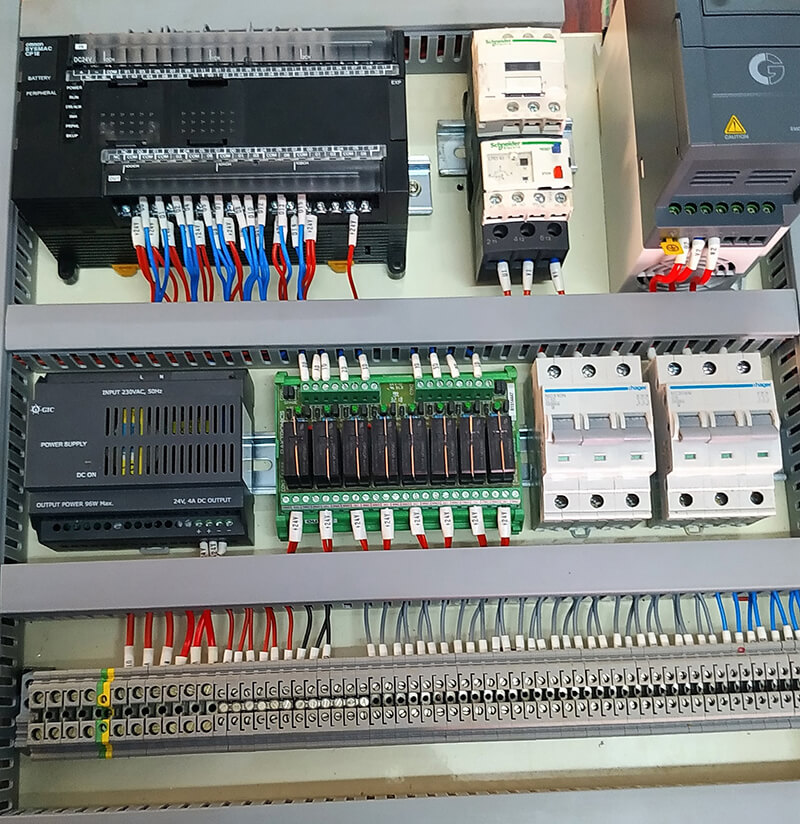

K-PAS CONVEYOR CONTROL PANEL is the heart of the control system that operationally brings together both the conveyor hardware and software of the system. Based on the type of conveyor and its requirements we at K-PAS will design the control panel and manufacture according to customer specification.

- Input Voltage : 230 V AC 50Hz

- Safety Integrated

- High performance

- High-performance technology

- Energy efficiency

- Advanced functions

- Communication standards

- PROFINET IO

- PROFIBUS DP V0/V1

- AS-Interface

- Point-to-point (RS 232, RS 485, RS 422)

- Increasing customer efficiency and productivity

- Improving quality of output through the automation of processes

- Reducing waste and scrap

- Increasing process up-time

- Creating solutions that are well-documented, aesthetically pleasing, and easy to troubleshoot in the field

- Constructing all electrical motor control panels to NFPA 79 and UL specifications with safety in mind

- Creating “operator friendly" industrial control panels

- Providing one-year parts and labor warranty on all electrical control panels and control systems

- Modular configuration with up to 64 modules

- System-integrated self-assembling load group supply without power module via light BaseUnits

- Small size and highly flexible due to the modular design and comprehensive product range

- Up to 16 channels per module

- Hot swapping: Module replacement without tools in RUN

- Operation with gaps

- Optimum accessibility for wiring due to spring release and measuring tap next to the conductor opening

- Flexible PROFINET connection via BusAdapter (RJ45, FastConnect, plastic or glass fiber-optic cables), also as integrated media converter

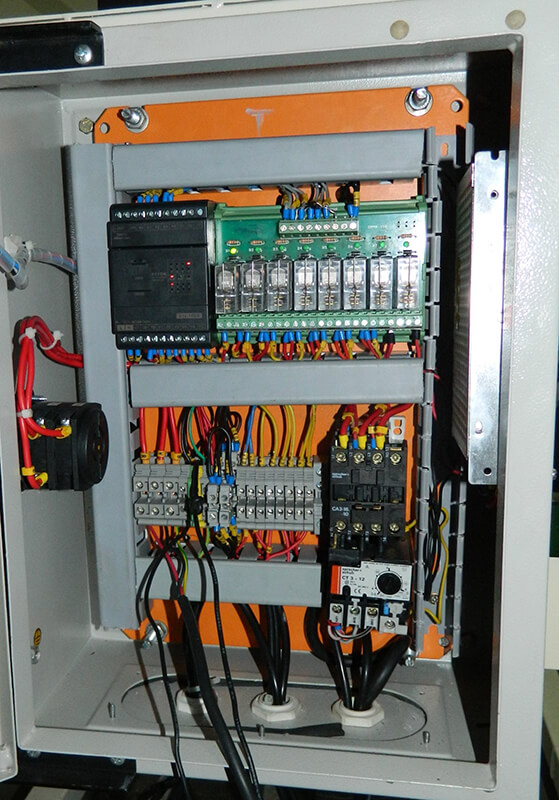

K-PAS MOTOR CONTROL CENTRE is the heart of the control system that operationally brings together both the Motor hardware and software of the system.Based on the type of Motor and its requirements we at K-PAS will design the control panel and manufacture according to customer specification.

| Input Voltage |

|

| Rotation | CCW (VIEW FROM MOTOR DRIVE END) |

| TEMPERATURE | 30-55 DEG CELCIUS |

| Humidity | Enclosed type MAX 95% RH |

| Cooling | Fan Cooled |

- Increasing customer efficiency and productivity

- Improving quality of output through the automation of processes

- Reducing waste and scrap

- Increasing process up-time

- Creating solutions that are well-documented, aesthetically pleasing, and easy to troubleshoot in the field

- Constructing all electrical motor control panels to NFPA 79 and UL specifications with safety in mind

- Creating “operator friendly" industrial control panels

- Providing one-year parts and labor warranty on all electrical control panels and control systems

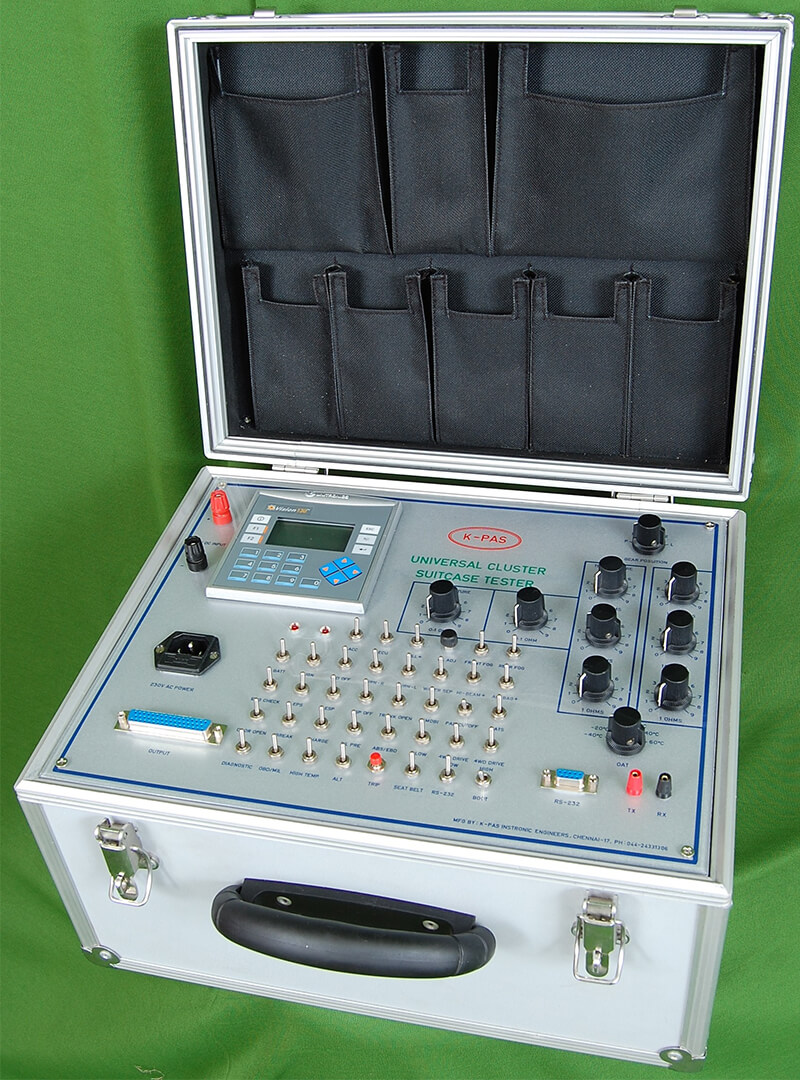

Extensively applicable in PLC programming, the range of Cluster Endurance Test Rigs that we offer is specifically manufactured using excellent grade components and with the aid of latest technologies. Post manufacturing the range undergoes stringent checks and tests to ensure delivery of only defect free range at client’s destination. K-PAS Cluster Endurance Unit is used to check the working condition of all the functions in the cluster unit of a Motorcycle.

| Sr. No. | Description | I/P for Cluster | I/P for Data Logger | I/P Specification |

|---|---|---|---|---|

| 1 | Brake Vacuum Pump | CAN MSG from Data logger | 12 VDC 12 VDCGround | Gnd Reference w.r.t 12 VDC ( low) |

| 2 | Engine Brush Wear | CAN message from Data Logger | + 96 VDC | + 96 VDC |

| 3 | High Beam | Active Low 12 VDC Ground | N/A | N/A |

| 4 | Turn Signal Indicator | Active High Signal 12 VDC + Ve | N/A | N/A |

| 5 | Economy | CAN message from Data Logger | 12 VDC | 12 VDC (High) |

| 6 | Power Charge Plug inserted | Active Low 12 VDC Ground | N/A | N/A |

| 7 | EPS | When CAN bus not connected EPS LED get continuous ON.i.e. EPS LED get ON every time as cluster get ON. | ||

| 8 | Engine temperature | CAN message from Data Logger | REFER BLINK CODE DETAILS. (After giving 8 pulses of blink code to the data logger CAN message will generate.) | |

| 9 | Auxiliary 12 V battery Low | CAN message from Data Logger | 12 VDC | 12 VDC (High) |

| 10 | DC DC convertor | CAN message from Data Logger | 12 VDC 12 VDCGround | Gnd Reference w.r.t12 VDC ( low) |

| 11 | Park Brake | Active Low 12 VDC Ground | N/A | N/A |

| 12 | Brake Oil | Active Low 12 VDC Ground | N/A | N/A |

| 13 | Speedo meter/ Ammeter / Voltmeter | +12 VDC | N/A | N/A |

| 14 | LCD Display | +12 VDC | N/A | N/A |

| 15 | Pointer | +12 VDC | N/A | N/A |

- Resistance against corrosion and wear and tear

- Durable and reliable

- Low maintenance requirement

- Small and Portable

- Highly Accurate

- Speedometer Testing

- Range Of Voltage: 70 VDC to 115 VDC

- Range of Current: -50 A to 300 A

- Battery Charge Indication on LCD.

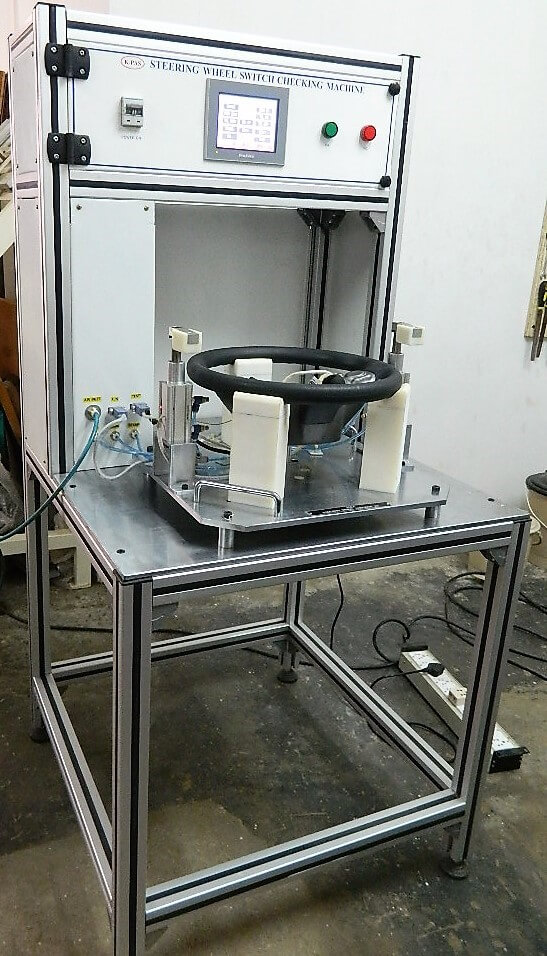

Final assemble check station designed for to check steering parts and checkpoints checked by sensors and controlled by PLC as per customer specifications. This machine is operated by manually with specific sequence. This machine also check the different models by manually change over 4 different fixtures.

| OPERATION | MANUAL |

| POWER INPUT | 230 V AC Single PhaseAC 50Hz ±10% |

| RATING | 6 AMPS |

| AIR PRESSURE | 6 BAR |

| OPERATING TEMP. | 20 – 45 degrees |

- Auto selector in auto mode

- Clamp lock cylinder-up position

- Model selected 1/2/3

- Clamp cylinder clamp movement

- Safety sensor utilized

- PLC and HMI for faster and accurate check system