This ORVM Cable Durability Tester is a Testing Equipment Manufactured by K-PAS tests the Durability of the Mirror by Moving the Mirror in the applied directions continuously. The current testing will be used to test the MM5 Model.

The Maximum number of Mirrors which can be tested simultaneously is 6 Mirrors.

Our Actuator Manual Durability Tester uses the Latest Allen Bradley PLC and its NI LABVIEW Software so as to get fast and accurate Real Time Results for the UUT(Unit Under Test).

The Continuous Folding and Unfolding Test to be done for the Mirror for the required number of Cycles is carried out in this ORVM CABLE DURABILITY TESTER.

- INPUT VOLTAGE 230V 50HZ

- MITSUBISHI DRIVE 2.0 kHz speed Frequency Response

- ENCODER DC 24V

- PLC Calculates the exact status of field devices and also acts as a tool to control them

- OPERATING TEMPERATURE PLC AND PC ROOM TEMPERATURE 25-45 Deg

- Ni Labview Utilized.

- Aluminium Profile for High Durability

- High Accuracy based On PLC

- High Durable Machine

- Servo Motor for Precise Movement of Mirrors

- Real time Current and Voltage Monitor

- Data Capture using Lab view

This ORVM Manual Folding Durability Tester is a Testing Equipment Manufactured by K-PAS tests the Durability of the Mirror by Moving the Mirror in the applied directions continuously. The current testing will be used to test the MM5 Model.

The Maximum number of Mirrors which can be tested simultaneously is 6 Mirrors.

Our Manual Folding Durability Tester uses the Latest Allen Bradley PLC and its HMI so as to get fast and accurate Results for the UUT(Unit Under Test).

The Manual Folding Durability test are done both in Manual Mode and in Auto Mode .

There are two Servo Motors connected to the Mirror setup to run the Folding and the Unfolding Process continuously for a long time.

- INPUT VOLTAGE 230V 50HZ

- MITSUBISHI DRIVE 2.0 kHz speed Frequency Response

- ENCODER DC 24V

- PLC Calculates the exact status of field devices and also acts as a tool to control them

- OPERATING TEMPERATURE PLC AND PC ROOM TEMPERATURE 25-45 Deg

- Ni Labview Utilized.

- Aluminium Profile for High Durability

- High Accuracy based On PLC

- High Durable Machine

- Servo Motor for Precise Movement of Mirrors

- Realtime Current and Voltage Monitor

- Data Capture using Labview

- Manual Movement of Mirror through Servo Meter

- Network support includes EtherNet/IP™, DeviceNet™, and DH-485 (local only).

- Built-in LCD with backlight lets you view controller and I/O status.

- Built-in LCD provides simple interface for messages, bit/integer

- monitoring and manipulation.

- Omron Make pluggable Relay.

This Actuator Manual Durability Tester is a Testing Equipment Manufactured by K-PAS tests the Durability of the Mirror by Moving the Mirror in the applied directions continuously. The current testing will be used to test the MM5 Model.

The Maximum number of Mirrors which can be tested simultaneously is 16 Mirrors.

Our Actuator Manual Durability Tester uses the Latest Allen Bradley PLC and its HMI so as to get fast and accurate Results for the UUT(Unit Under Test).

The Number of Cycles Run corresponds with the Durability of the Mirror i.e., the Longer the Mirror is tested without any problems, the better the Durability.

- INPUT VOLTAGE 230V 50HZ

- Constant Pressure of 4-6 Bar with Reservoir Tank

- PLC Calculates the exact status of field devices and also acts as a tool to control them

- OPERATING TEMPERATURE PLC AND PC ROOM TEMPERATURE 25-45 Deg

- HMI used for real time process and control.

- Aluminium Profile for High Durability

- Cylinders fitted on Aluminium Plate

- High Accuracy based On PLC

- Temperature chamber tester with high Temperature

- High Durable Cylinders utilized.

- Servo Motor for Precise Movement of Mirrors

- Realtime Current and Voltage Monitor

- Data Capture using Labview

- Manual Movement of Mirror through Servo Meter

- Network support includes EtherNet/IP™, DeviceNet™, and DH-485 (local only).

- Built-in LCD with backlight lets you view controller and I/O status.

- Built-in LCD provides simple interface for messages, bit/integer monitoring and manipulation.

- Omron Make pluggable Relay.

This Electric Durability Tester is a Testing Equipment Manufactured by K-PAS tests the Durability of the Mirror by Moving the Mirror in the applied directions continuously. The current testing will be used to test the MM5 Model.

The Maximum number of Mirrors which can be tested simultaneously is 6 Mirrors and more based on customer requirement Our Manual Folding Durability Tester uses the Latest Allen Bradley PLC and its HMI so as to get fast and accurate Results for the UUT(Unit Under Test).

The ELECTRIC Folding Durability test are done both in Manual Mode and in Auto Mode.

The Mirrors (UUT) are placed inside the CHAMBER which is used to HEAT and COOL the UUT’s where they are tested in different Temperatures to ensure their Durability upon use in

Various Regions with Different Climatic Conditions

- INPUT VOLTAGE 230V 50HZ

- PLC Calculates the exact status of field devices and also acts as a tool to control them

- OPERATING TEMPERATURE PLC AND PC ROOM TEMPERATURE 25-45 Deg

- HMI used for real time process and control.

- Aluminium Profile for High Durability

- Electric Mirrors directly connected on the Aluminium Profile and used for testing.

- High Accuracy based On PLC

- Temperature chamber tester with high Temperature

- Realtime Current and Voltage Monitor

- Data Capture using Labview

- Manual Movement of Mirror through Servo Meter

- Network support includes EtherNet/IP™, DeviceNet™, and DH-485 (local only).

- Built-in LCD with backlight lets you view controller and I/O status.

- Built-in LCD provides simple interface for messages, bit/integer monitoring and manipulation.

- Omron Make pluggable Relay.

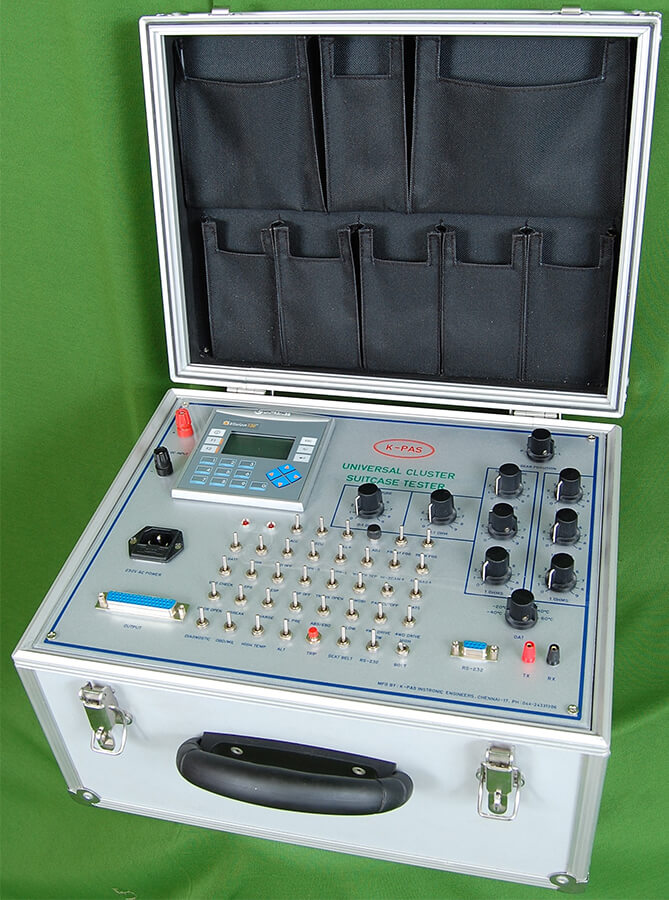

K-PAS Cluster Testing Unit is used to check the working condition of all the functions in the cluster unit of a Motor Cycle.

| Sr. No. | Description | I/P for Cluster | I/P for Data Logger | I/P Specification |

|---|---|---|---|---|

| 1 | Brake Vacuum Pump | CAN MSG from Data logger | 12 VDC 12 VDCGround | Gnd Reference w.r.t 12 VDC ( low) |

| 2 | Engine Brush Wear | CAN message from Data Logger | + 96 VDC | + 96 VDC |

| 3 | High Beam | Active Low 12 VDC Ground | N/A | N/A |

| 4 | Turn Signal Indicator | Active High Signal 12 VDC + Ve | N/A | N/A |

| 5 | Economy | CAN message from Data Logger | 12 VDC | 12 VDC (High) |

| 6 | Power Charge Plug inserted | Active Low 12 VDC Ground | N/A | N/A |

| 7 | EPS | When CAN bus not connected EPS LED get continuous ON.i.e. EPS LED get ON every time as cluster get ON. | ||

| 8 | Engine temperature | CAN message from Data Logger | REFER BLINK CODE DETAILS. (After giving 8 pulses of blink code to the data logger CAN message will generate.) | |

| 9 | Auxiliary 12 V battery Low | CAN message from Data Logger | 12 VDC | 12 VDC (High) |

| 10 | DC DC convertor | CAN message from Data Logger | 12 VDC 12 VDCGround | Gnd Reference w.r.t12 VDC ( low) |

| 11 | Park Brake | Active Low 12 VDC Ground | N/A | N/A |

| 12 | Brake Oil | Active Low 12 VDC Ground | N/A | N/A |

| 13 | Speedo meter/ Ammeter / Voltmeter | +12 VDC | N/A | N/A |

| 14 | LCD Display | +12 VDC | N/A | N/A |

| 15 | Pointer | +12 VDC | N/A | N/A |

- Small and Portable

- Highly Accurate

- Speedometer Testing

- Range Of Voltage: 70 VDC to 115 VDC

- Range of Current: -50 A to 300 A

- Battery Charge Indication on LCD.