Supported by a team of talented engineers and technicians, we have been able to design and manufacture a wide range of Special Purpose Machines. In strict compliance with industry norms and standards, these machines are fabricated using high grade raw material and components. Moreover, the range is offered in customized specifications based on the details provided by the clients.

K-PAS Core Builder is designed specially for assembly of components such as FIN, Radiator and other tubing to form a Radiator Core thus our Machine is names Core Builder. This can also be used for Condenser type Core.

K-PAS custom engineered Core Builders and Assembly Systems can provide manual, semi-automated and highly automated assembly of all heat exchangers types and other products made from light gauge components.

- 2-3 components assembled per minute

- Highly Accurate and precisely Engineered

- Minimum Maintenance

- PLC and HMI used for Fast and accurate response

- Assembly cycle time reduction features

- Stand alone type core builder

- System Integration with existing equipment and machines

- Servo driven core compression & header insertion

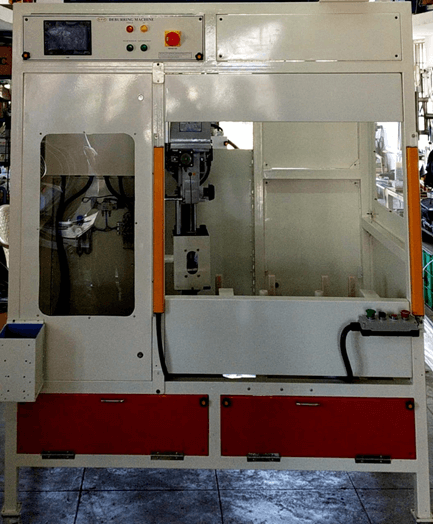

This machine is designed in single station for remove the flash in the injection moulded AIM part in 6 positions. The machine basically consists of the following system integrated.

- Mechanical

- Electrical

- Pneumatic

MACHANICAL:

The Machine consists of a table made up of MS Tube, and L angle which is mounted on the integrated Boot and wheel base. The part locates in a movable fixture.

ELECTRICAL:

This machine consists of ELECTRICAL control Panel With PLC, SMPS, Power and control terminals, The front end panel of the machine is consists of HMI, Push button and indicators.

PNEUMATIC:

The Pneumatic Control of the machine is made by the combination of FRL, Solenoid Valve, and Cylinder.

| COMPONENT | AIM- (Air Intake Manifold) |

| MACHINE NAME | Deburring Machine |

| OVERALL DIMENSIONS | 1700*850*1790(L*W*H) mm |

| LINE PRESSURE | 4-6 bar |

| GROSS WEIGHT | 400 Kg |

| INPUT SUPPLY | 415V 3 Phase AC Supply |

| LOAD CONNECTED | 3500 W (Including Vacuum Cleaner) |

| CONTROL SUPPLY | +24V DC Supply |

- AUTO MODE,MANUAL MODE, SEMI AUTO MODE

- PRECISE DEBURRING PROCESS

- PNEUMATIC BASED ACCURATE SYSTEM

- < 1MIN PER PIECE FOR DEBURRING

- HIGHLY DURABLE

- HMI TO CONTROL THE PROCESS

- PLC USED FOR BETTER PRECISION AND TIMING ACCURACY

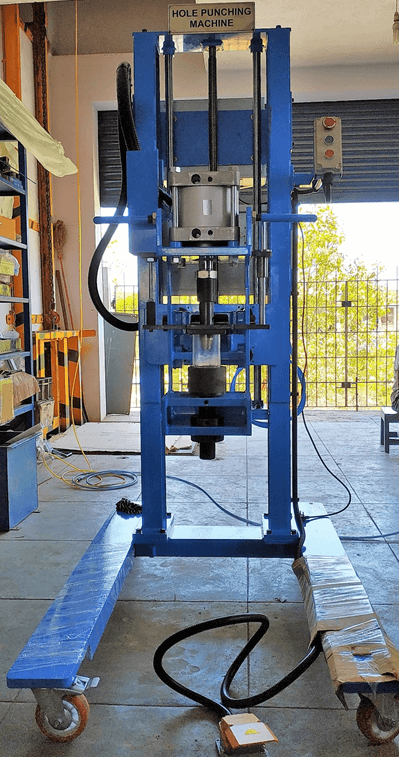

K-PAS HOLE PUNCHING MACHINE is a Mechanical Machine designed for the purpose of making holes in the Expansion Joint Fabric. We have provided with two different regulators for maintain different pressure for the punching tool and the safety guard provided with it.

K-PAS Hole Punching Machine is a Machine Integrated with Both Electrical as well as Pneumatic Components to give Accurate Results and Timely Process. The Hole Punching Machine can be Moved in a Vertical Direction from the Bottom to the Top with the help of the Wheel provided at the bottom of the Machine.

The Hole Punching Machine can be Operated in 2 Positions

- Horizontal

- Vertical, whose positions can be changed by Removing the Two Allen Screw on either sides of the Machine.

The Pressure applied to the Punching Tool is 7 Bar Max and to be constantly provided for continuous running of the Hole Punching Machine.

The Pressure applied to the Safety Guard(Acrylic Cover) is 2 Bar Max and to be also provided constantly.

| INPUT VOLTAGE | 230V AC, 50HZ |

| PROTECTION | DOOR SWITCH FOR THE DOOR TO SWITCH OFF THE SUPPLY OF THE PANEL AND SEPARATE REGULATORS FOR BOTH CYLINDERS. |

| OPERATION | HOLE PUNCHING IN THE EXPANSION JOINT FABRIC |

| OPERATING PRESSURE |

|

- Expansion joint Hole punching

- Can be used for Many types of expansion joint fabric

- Highly safe

- Production based Machine

- Highly Durable

- Immediate Service

This Core Squeezing & Sizing Machine is developed with the purpose of reducing the size of the Core and Mantle to the given specification thus meeting the Customer Requirement.

| COMPONENT | Core and Mantle |

| MACHINE NAME | CORE SQUEEZING AND SIZING MACHINE |

| LINE PRESSURE | 160-200 bar |

| GROSS WEIGHT | 500 kg including power pack and chillers |

| INPUT SUPPLY | 3 PHASE 415V AC |

| LOAD CONNECTED | 8 kW |

| CONTROL SUPPLY | +24V |

| PLC USED | MITSUBISHI |

- Coolant provided to prevent heating

- Continuous Production Unit

- Highly accurate Shrinking of the core part

- High Pressure Motor can withstand longer

- Auto and Manual Sequence present

- PLC for high accuracy

K-PAS Bearing Grease Machine is designed specially for the dispersion of grease to the Bearing part through Auto Mode. A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. So applying grease improves the movement and reduces the friction and provides long life through reduced maintenance.

| INPUT VOLTAGE | 230V AC, 50HZ |

| GROSS WEIGHT | <300 kg |

| LINE PRESSURE | 3-4 bar |

| PLC | Mitsubishi |

| Based on type of clip | 8-12 components per minute |

- Pneumatic based filling process

- Improved speed and filling capacity based on Bearing Type

- Minimum 3-10Kg Grease Reservoir Capacity

- Auto and Manual Sequence present

- PLC for high accuracy

- Production based Machine

- Highly Durable

- Immediate Service

Clip fitting machine is designed for the assembly of the clip in the tow bar boot as per customer specifications. This machine is operated by pneumatic cylinders with specific size and model. This machine also check the condition of the boot puncture through pressing the boot after clip fitting.

| INPUT VOLTAGE | 230V AC, 50HZ |

| GROSS WEIGHT | <150 kg |

| LINE PRESSURE | 3-5 bar |

| PLC | Mitsubishi |

| HMI | Delta (based on customer requirement) |

| Based on type of clip | 5-10 components per minute |

- Highly Accurate and precisely Engineered

- Minimum Maintenance

- PLC and HMI used for Fast and accurate response

- Assembly cycle time reduction features

- Auto and manual Mode for easy operations

- Safety procedure given for assembly